Dimensional measurement

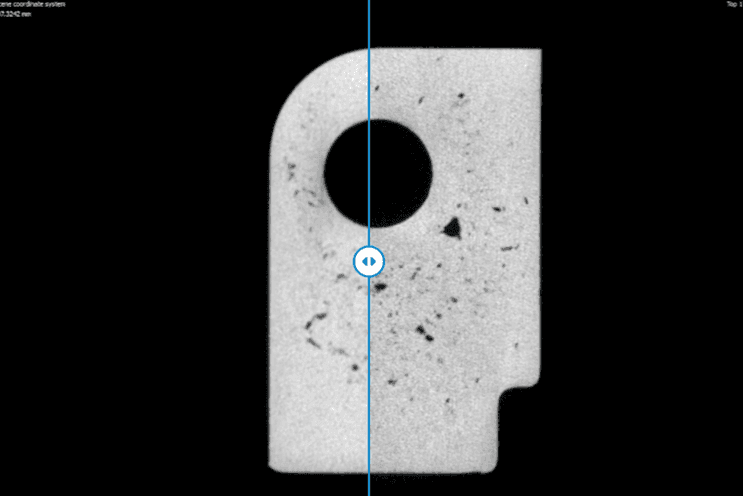

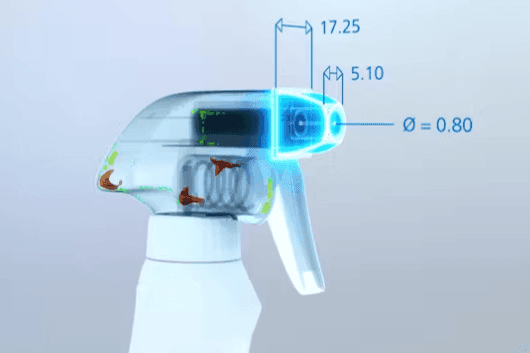

Using computerized tomography, you can obtain precise measurements of three-dimensional parts, including standard geometry and freeform surfaces. This can help ensure compliance with technical specifications and tolerances.

Always benefiting form the cutting-edge technology (software and hardware) of the German manufacturer ZEISS, we offer metrology services using computerized tomography (X-Ray scanning).

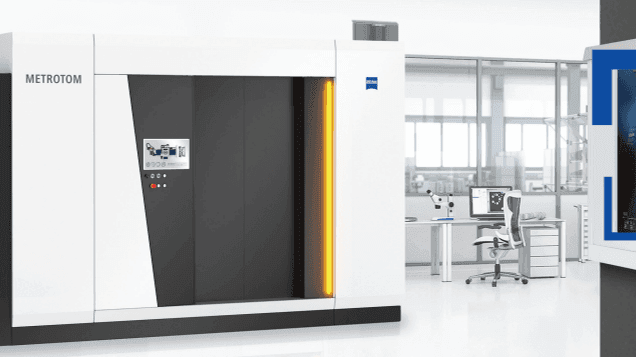

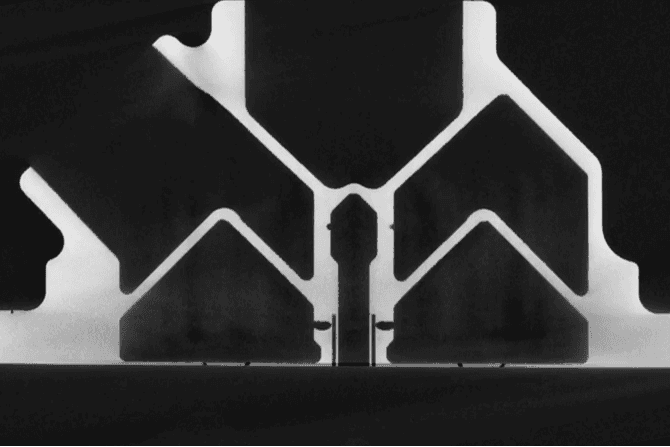

Industrial X-Ray CT Scanning (Computed Tomography) is an advanced non-destructive 3D inspection and measurement technology used to analyze both the external geometry and the internal structure of industrial parts. The process involves using X-rays to generate a complete three-dimensional reconstruction of the inspected part—without disassembling or damaging it. In our Brașov laboratory, we use the latest generation ZEISS METROTOM 1500 system, a high-precision industrial CT scanner ideal for metrology applications, quality control, and the detection of hidden defects.

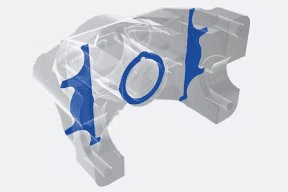

The result: a detailed volumetric model that enables internal analysis, CAD comparison, precise dimensional measurements, and automatic defect detection.

METROTOM 1500 is a high-performance X-ray tomograph designed to provide detailed three-dimensional images of parts and components. This advanced tool uses X-rays to visualize internal details without affecting the integrity of the part.

| Measurement volume | In image | Ø 330 mm, h 270 mm |

| Maximum workpiece dimensions | With maximum vertical field of view extension | Ø 330 mm, h 870 mm |

| With maximum vertical and horizontal field of view extension | Ø 615 mm, h 800 mm | |

| Optimized for maximum diameter | Ø 770 mm, h 1.350 mm | |

| Optimized for maximum height | Ø 516 mm, h 1.500 mm | |

| Weight | Maximum workpiece weight | 50 kg |

With the ZEISS Metrotom 1500 equipment and a specialized team, we offer professional industrial CT scanning services in Brașov, meeting requirements for:

Obtain clear and precise images of the internal structure, including complex assemblies.

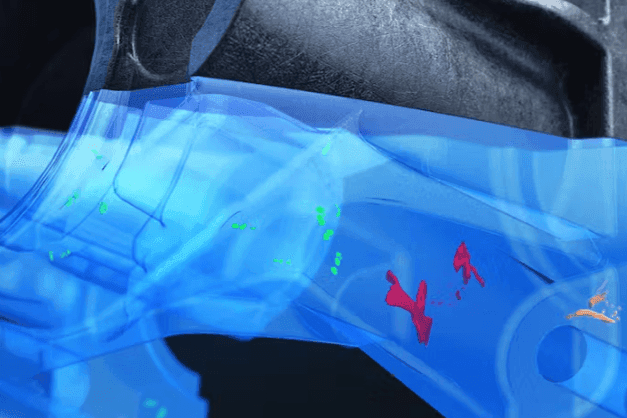

Identify defects, cracks, irregularities, inclusions, and porosity invisible to the naked eye.

Perform inspections of assembled parts without damaging or degrading the components.

Accurate data obtained provide support for improving and developing production processes.

Perform accurate measurements of the dimensions and geometry of components.

Join the most important events and stay up to date with the latest industry news

Avem plăcerea de a vă invita la evenimentul de inaugurare a noului laborator de măsurări din Timișoara, unde vă vom prezenta soluții pentru controlul calității, pe 19 Martie, începând cu ora 09:30. Experimentați universul metrologiei în cadrul unei expoziții interesante și prin prezentări interactive!

Pe 6 Noiembrie, pregatiți-vă pentru un workshop exclusiv dedicat profesioniștilor în controlul calității. Descoperiți soluții concrete pentru provocările din producție, participați la demonstrații live cu echipamente de ultimă generație și beneficiați de consultanță personalizată pentru a vă optimiza procesele de măsurare.

We invite you to an event dedicated to the latest technical solutions in the field of turning and grinding! Together with our top partners – BRUCKNER, BLOHM JUNG, INDEX, STUDER, WALTER EWAG – you will explore the most advanced technologies and attend live demonstrations that will address the needs and challenges you face in your activity.

Vă invităm la un nou eveniment anual exclusiv în care vom prezenta pentru a treia oară soluții de asigurare a calității împreună cu partenerul nostru ZEISS. Explorați împreună cu noi lumea metrologiei industriale ZEISS..