What is Reverse Engineering?

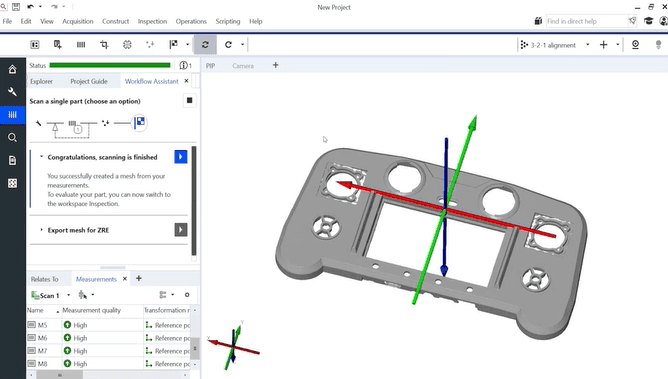

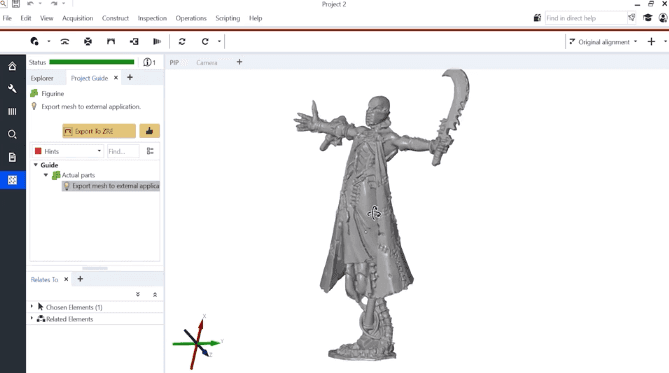

Reverse Engineering is the process by which a physical part is converted into a 3D CAD digital model using advanced 3D scanning and dimensional inspection technologies.

This process is essential for:

- Reproducing parts without CAD documentation

- Optimizing existing products

- Redesigning for functional or aesthetic improvement

- Quality control and comparison between the physical part and the digital model

Discover new opportunities through our reverse engineering service

With advanced technologies and a dedicated specialist team, we guarantee precise digital solutions for your specific needs.

Served industries and applicability

Automotive

- Reverse Engineering for Freeform Surfaces

- Calculation of the combustion chamber volume

- Remodeling of irregular shapes

Aerospace

- Reverse engineering for turbine blades

- Prototyping and testing

- Redesign of critical parts

Machinery and Tooling Engineering

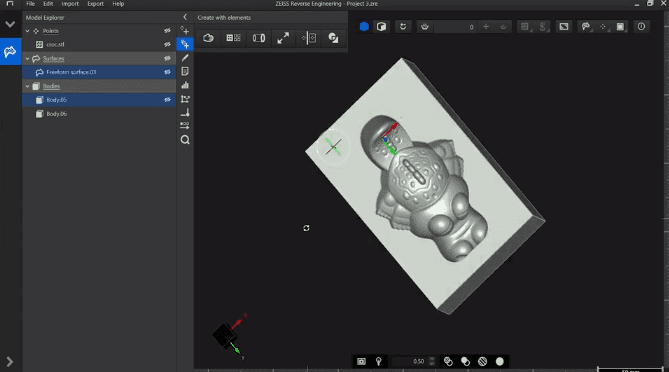

- Reverse engineering for mold injection

- Reverse engineering for gears

- Tool correction for stamping dies

Medical

- Reverse engineering for prosthetics

- Customized implants

- Components for medical equipment

Contact Us for a Personalized Quote

If you have a part without documentation or want to improve an existing product, contact us today for a free evaluation. Send us a model, a part, or a drawing, and we will provide you with fast and accurate solutions.

Contact usBenefits of our Reverse Engineering services

By using state-of-the-art ZEISS quality control equipment, we offer our clients complete reverse engineering solutions tailored to their industry and specific technical requirements.

Here’s what sets us apart:

Guaranteed precision: We use ZEISS optical 3D scanners and CMMs to obtain highly accurate digital models that meet the strict requirements of the automotive, medical, and aerospace industries.

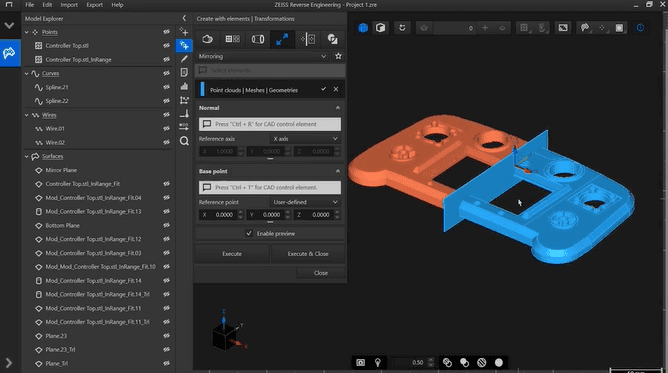

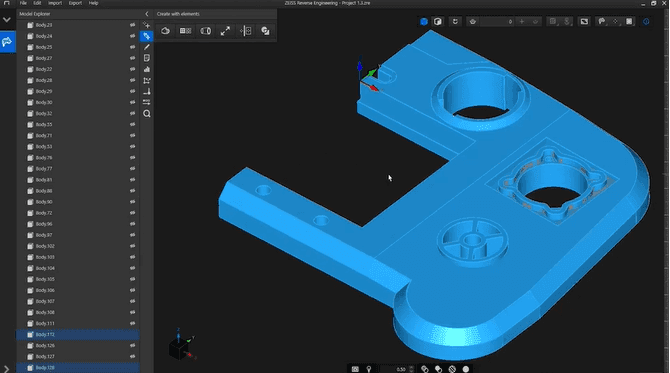

Complete and reliable CAD reconstruction: We convert physical components into 3D CAD models (STEP, IGES, STL), ready for design, simulation, or manufacturing. Whether you have technical drawings or not, we accurately recreate the exact geometry of the part.

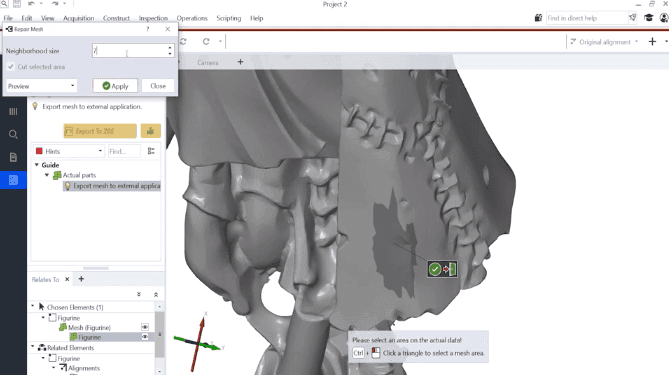

Support for any type of part – Simple or complex: Regardless of shape, size, or industry, we can scan and reconstruct a wide range of parts and components so you can benefit from the digital model.

Time and cost savings in development or maintenance: Through reverse engineering, we eliminate the need for redesigning from scratch. You quickly get a precise digital part, reducing downtime and costs associated with repair or replacement of worn components.

CAD model for any part regardless of its complexity

Standard geometric shapes:

With the help of the complex functions of the supplied software, we can create new shapes, extract certain parts of the part from the whole and adjust the desired parts.

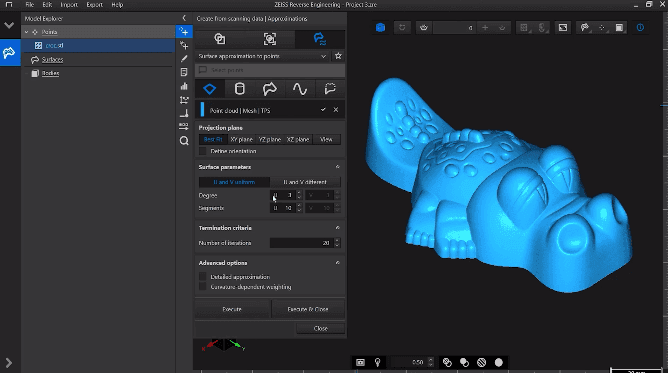

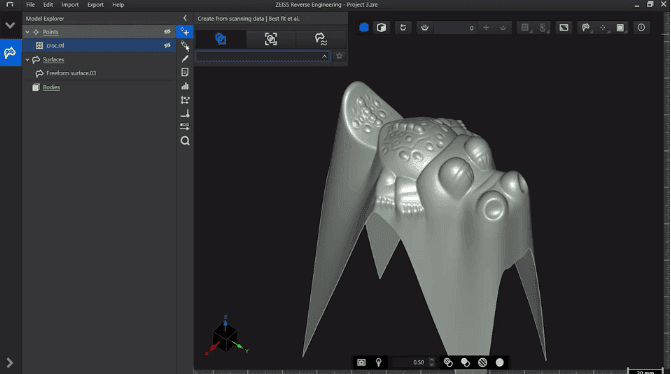

Free surfaces:

We can obtain extremely precise free-form surfaces after scanning your parts.

Irregular shapes:

Precise reshaping of irregular shapes with the help of special ZEISS tools.

Aplications

Document retrieval

Sometimes, the original documentation of a product or component may be lost or outdated. Reverse engineering can be used to recreate or obtain relevant data and documentation about the product or component in question.

Spare parts for a product

When spare parts for a product are hard to find or no longer available, reverse engineering can be used to recreate these parts or compatible replacement components.

Academic purposes

Reverse engineering can be a learning or research activity used in the academic environment to better understand the design principles, technologies, and processes behind existing products.

Do you need 3D measurement or Reverse engineering services?

Contact us now to discuss with a specialist!

Contact usNews and events

Join the most important events and stay up to date with the latest industry news

Forumul de Inovație ZEISS & Marea Deschidere INMAACRO Timișoara I 19.03.2026

Avem plăcerea de a vă invita la evenimentul de inaugurare a noului laborator de măsurări din Timișoara, unde vă vom prezenta soluții pentru controlul calității, pe 19 Martie, începând cu ora 09:30. Experimentați universul metrologiei în cadrul unei expoziții interesante și prin prezentări interactive!

Ziua Calității ZEISS 2025 | 06.11.2025

Pe 6 Noiembrie, pregatiți-vă pentru un workshop exclusiv dedicat profesioniștilor în controlul calității. Descoperiți soluții concrete pentru provocările din producție, participați la demonstrații live cu echipamente de ultimă generație și beneficiați de consultanță personalizată pentru a vă optimiza procesele de măsurare.

Technical News in Turning and Grinding – WORKSHOP | 08.05.2025

We invite you to an event dedicated to the latest technical solutions in the field of turning and grinding! Together with our top partners – BRUCKNER, BLOHM JUNG, INDEX, STUDER, WALTER EWAG – you will explore the most advanced technologies and attend live demonstrations that will address the needs and challenges you face in your activity.

Ziua Calității ZEISS 2024 | 21 Noiembrie 2024

Vă invităm la un nou eveniment anual exclusiv în care vom prezenta pentru a treia oară soluții de asigurare a calității împreună cu partenerul nostru ZEISS. Explorați împreună cu noi lumea metrologiei industriale ZEISS..