3D Scanning and Precision Measurement

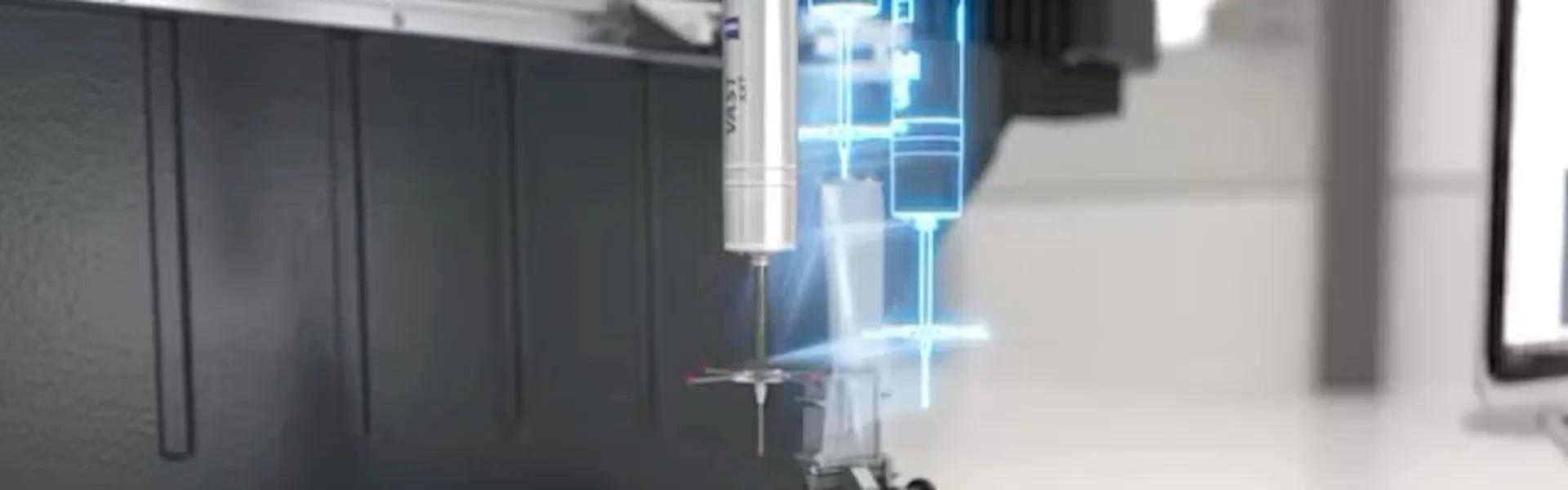

Our industrial 3D scanning service is designed for the precise measurement of parts, components, and assemblies, regardless of their complexity. We use state-of-the-art ZEISS industrial 3D scanning equipment to obtain accurate digital models, ideal for quality control, comparison between the physical part and the CAD model, or reverse engineering. With quality control laboratories located both in Brașov and Timișoara, we aim to be as close as possible to you for all projects requiring high-precision 3D measurement and scanning.

We use non-invasive, fast, and precise methods to deliver reliable results in a short time, through a process conducted entirely either at our facility or directly at your site.

Equipment used for 3D scanning and measurement:

With the help of advanced X-Ray technology we obtain fast and high-resolution data for both small and large parts. The system used ensures an undisputed quality of the obtained data and makes it an ideal equipment for inspecting parts of several materials.

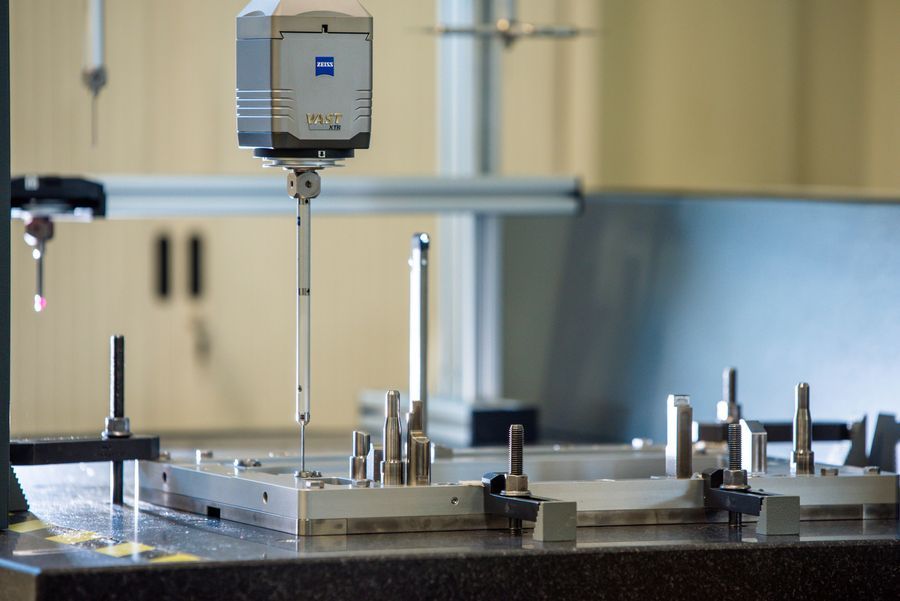

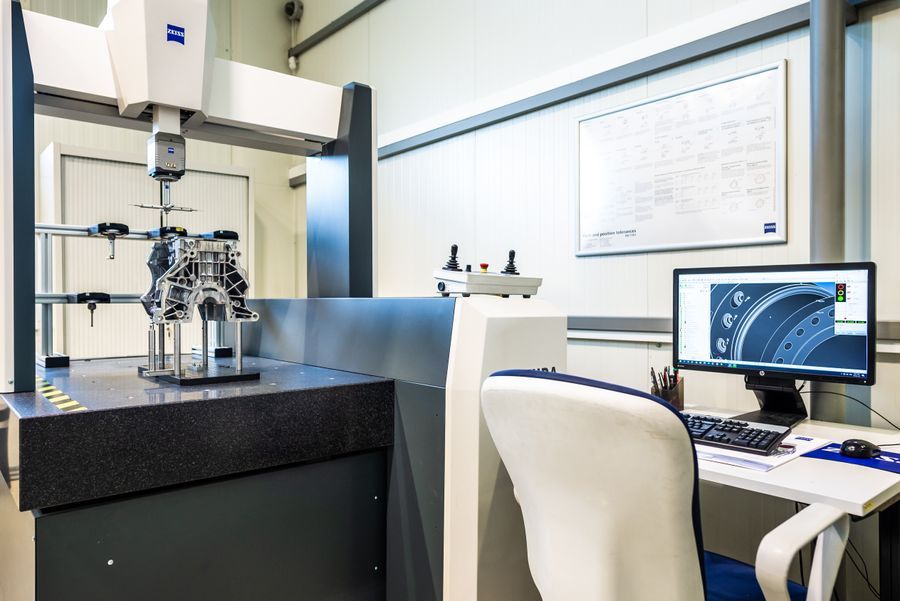

The ZEISS Accura II coordinate measuring machine is an essential tool in quality control, providing accurate and fast measurement of complex parts. Using 3D measurement technology, it allows detailed inspection of the dimensions, shape and position of parts, ensuring they meet technical specifications.

With robust construction and advanced technology, it allows us to make precise measurements of complex parts, checking their shapes, sizes and tolerances. ZEISS CONTURA ensures fast and accurate results, even for components with difficult geometry, being ideal for applications in industries such as automotive, aerospace and metalworking.

With its compact design, the ZEISS DuraMax 3D Coordinate Measuring Machine (CMM) allows us to perform fast and accurate 3D measurements of parts, regardless of their complexity. This CMM is ideal for verifying the dimensions, shape, and tolerances of mechanical components in industrial or production environments. Thanks to ZEISS's advanced technology, the DuraMax ensures precise quality control and contributes to the improvement of manufacturing processes.

ZEISS O-INSPECT allows us to carry out precise inspections of complex parts by using tactile and optical sensors that enable fast and highly accurate measurements. This machine is ideal for checking detailed geometry, complex tolerances and dimensions.

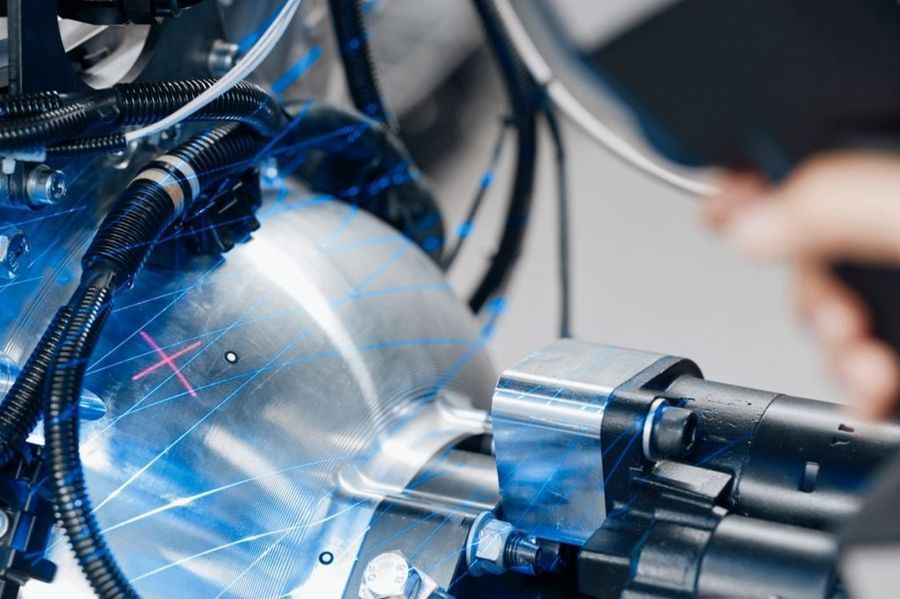

ZEISS ATOS Q is a high-precision 3D measuring system used to capture the complex details of parts through optical scanning technology. Due to the speed and accuracy of the results, ATOS Q is indispensable for us to perform fast and accurate inspections of parts, obtaining accurate digital models that allow us to analyze their shapes, sizes and tolerances.

This portable scanner enables fast and precise measurements of part geometry, regardless of their size or complexity. Utilizing advanced technology, the T-Scan HAWK 2 provides efficient solutions for quality inspection, reverse engineering, and rapid prototyping, helping to maintain the highest technical and quality standards required by our clients. By integrating the T-Scan HAWK 2 into our 3D scanning services, we ensure comprehensive and accurate documentation of parts and assemblies, ideal for industrial and technical applications.

Advantages – Why choose our quality control services?

-Access to state-of-the-art technology

Without major investments we provide the latest 3D measurement and dimensional control equipment, so our partners do not need to invest in costly purchases, maintenance, or technical upgrades. Our infrastructure is continuously updated to ensure cutting-edge technology for every project. Through our 3D scanning services, we deliver fast, precise solutions aligned with the most demanding industry requirements.

-Support from a specialized quality control team

Our team consists of experts with extensive experience in 3D dimensional control, enabling us to be quick and efficient in task execution while guaranteeing high-quality results. We offer 3D scanning and measurement services for inspecting industrial parts and components, ensuring high accuracy at every stage of the process.

-Reliability, transparency, and long-term partnerships

Collaborating with us means building a relationship based on trust, transparency, and long-term commitment. We work closely with each client to thoroughly understand the specific project requirements, providing customized 3D measurement and dimensional control services tailored to each industrial context. With modern quality control laboratories in Brașov and Timișoara, we stay close to our partners to offer promptness, precision, and specialized local support.

-Safety and compliance with industry regulations

Our laboratory adheres to the strictest quality standards and regulations, ensuring that parts inspected through our 3D scanning and measurement services comply with industry regulatory requirements. This allows us to provide full confidence and safety in the results delivered.

Industries where our services apply – who are we addressing?

Automotive industry

Aerospace industry

Electronics industry

Electricity and energy industry

Medical industry

Mechanical processing industry

3D scanning and measurement applications

Complete product inspection for PPAP, ISR, and FAI processes

The process is carried out in a detailed and rigorous manner to ensure that the products meet the required standards and specifications before being delivered to customers or integrated into the production process.

Complete inspection for production process control

This process involves evaluating and monitoring each stage of production and the relevant processes to ensure that quality and performance standards are consistently met.

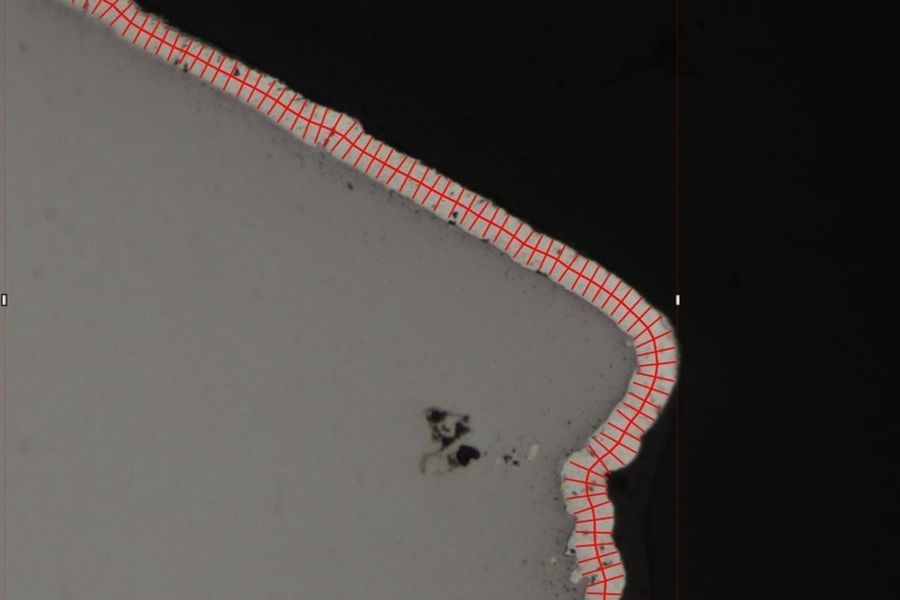

Analysis of complex shapes and freeform surfaces

This application is essential for evaluating and optimizing the design of complex parts, as well as for verifying their quality during the manufacturing process.

Compliance with ISO and ASME standards

We can accurately verify adherence to the dimensions and tolerances required by ISO and ASME standards, thereby ensuring product quality and eliminating risks associated with non-compliance.

Complete 3D inspection

An efficient and precise solution for evaluating and analyzing objects or areas of interest in a three-dimensional environment.

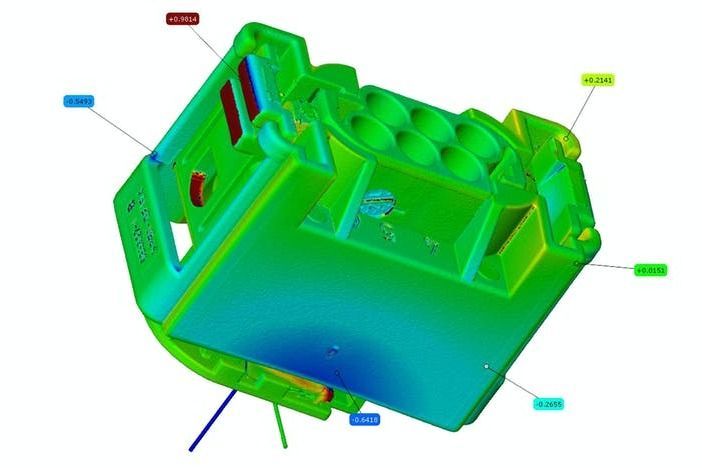

3D comparison between part and CAD model

An advanced method to verify and evaluate the accuracy and conformity between a CAD model and the physical part.

Analiza grosimii peretelui

Proces complex pentru a evaluarea integrității structurale a unei piese sau pentru a verifica conformitatea cu specificațiile de proiectare.

Tolerance and dimensional deviation verification

By accurately capturing the shape and geometry of the object, 3D scanning provides precise data that helps detect any non-conformities, thereby ensuring the quality and compliance of the final product.

100% Quality Guarantee!

We offer a 100% quality guarantee for our quality control services. Every measurement and inspection is performed with the highest precision, using state-of-the-art equipment and rigorous processes to ensure that the results always meet the requirements and expectations of our clients.

68% of companies that choose to outsource quality control services have reported significant cost savings and improved product quality.

Outsourcing quality control services offers substantial benefits to companies, such as cost reduction and access to cutting-edge technology. External providers have state-of-the-art measurement equipment and advanced software, enabling faster and more accurate inspection of parts, minimizing the risks of errors and product rejection. Furthermore, by saving resources allocated to personnel and infrastructure, companies can redirect these savings toward continuous process improvement, leading to higher quality and increased production efficiency.

How does the scanning process work?

Part shipment

Scanning

Results

Part return

Do you need 3D scanning services?

Contact us nowOther services you might be interested in

News and events

Join the most important events and stay up to date with the latest industry news

Ziua Calității ZEISS 2025 | 06.11.2025

Pe 6 Noiembrie, pregatiți-vă pentru un workshop exclusiv dedicat profesioniștilor în controlul calității. Descoperiți soluții concrete pentru provocările din producție, participați la demonstrații live cu echipamente de ultimă generație și beneficiați de consultanță personalizată pentru a vă optimiza procesele de măsurare.

Technical News in Turning and Grinding – WORKSHOP | 08.05.2025

We invite you to an event dedicated to the latest technical solutions in the field of turning and grinding! Together with our top partners – BRUCKNER, BLOHM JUNG, INDEX, STUDER, WALTER EWAG – you will explore the most advanced technologies and attend live demonstrations that will address the needs and challenges you face in your activity.

Ziua Calității ZEISS 2024 | 21 Noiembrie 2024

Vă invităm la un nou eveniment anual exclusiv în care vom prezenta pentru a treia oară soluții de asigurare a calității împreună cu partenerul nostru ZEISS. Explorați împreună cu noi lumea metrologiei industriale ZEISS..

INDUSTRY EXPO Arad | 31.10.2024

Și în acest an ne revedem la târgul Industry Expo & B2B Meeting Arad în data de 31.10.2024, începând cu ora 09:00. Suntem nerăbdători să împărtășim păreri și să găsim soluții pentru problemele cu care vă confruntați în procesul de producție.