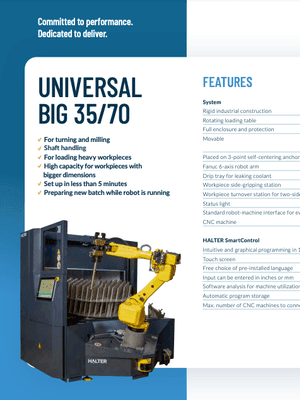

Halter Universal Big 35/70

Turning/Milling

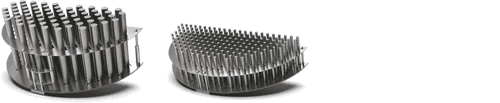

The Universal Big 35/70 is a robotic loading solution designed for turning and milling, with a focus on heavy workpiece loading. It also provides a substantial capacity for handling shafts of up to 600 mm.

Enhance your productivity with a setup time of less than 5 minutes, allowing you to prepare a new batch while the robot is in operation.

Your benefits with Halter

- Quick delivery

- Turn-key installation

- Local and remote support

- Attractive financing options

Extending Options

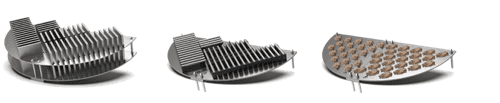

Universal Models Can Incorporate Added Functions

Customized Workpiece Solutions

Halter's application engineering team is equipped to create tailored solutions like custom grid plates and gripper fingers designed specifically for your unique workpieces. This level of customization is particularly beneficial when automating tasks involving special handling, such as castings. All these specialized solutions can be seamlessly integrated into the user-friendly HALTER SmartControl system. Our solutions' adaptability ensures that you can automate a wide range of workpiece variations

Shaft Handling

The HALTER Universal can be equipped with a shaft handling option, allowing you to load workpieces with heights of up to 600 mm, depending on the model. This option includes a comprehensive package featuring an additional 2-finger gripper, gripper fingers for various diameters, height-adjustable pins for grid plate support, and a regripping station

Optional Functionalities

- Unloading workpieces onto pallets

- Unloading workpieces at external fixed positions (e.g., conveyor belts)

- Removal of residual material

- Retrieving workpieces from revolver tools

- Cleaning workpieces outside the CNC machine

- Precise positioning of workpieces on measuring stations

- Efficient removal of rejected workpieces

- Secure workpiece side-gripping

- Accurate orientation of workpieces within CNC machine chucks

- Customized functionalities tailored to your specific requirements

Capacity & Specifications

System

| Feature | Description |

|---|---|

| Rigid industrial construction | ✓ |

| Rotating loading table | ✓ |

| Full enclosure and protection | ✓ |

| Movable | by 5 t forklift truck, crane |

| Placed on 3-point self-centering anchors | ✓ |

| Fanuc 6-axis robot arm | 35 kg / 70 kg |

| Drip tray for leaking coolant | ✓ |

| Workpiece side-gripping station | Option |

| Workpiece turnover station for two-sided machining | Option |

| Status light | Option |

| Standard robot-machine interface for every CNC machine | ✓ |

Halter Smartcontrol

| Feature | Description |

|---|---|

| Intuitive and graphical programming in 12 steps | ✓ |

| Touch screen | 21 inch |

| Free choice of pre-installed language | ✓ |

| Input can be entered in inches or mm | ✓ |

| Software analysis for machine utilization | ✓ |

| Automatic program storage | ✓ |

| Max. number of CNC machines to connect with | 4 |

Halter Smartcontrol Standard Functionalities

| Feature | Option |

|---|---|

| Positioning workpiece in machine vise with soft push function | ☑ |

| Workpiece regripping for accurate positioning | ☑ |

| Unload-only function in combination with bar feeder | ☑ |

| Inside and outside gripping | ☑ |

| Workpiece loading in chuck with or without pressure star | ☑ |

| Adjusting airblow distance | ☑ |

| Working with spindle orientation of the CNC machine | ☑ |

| Eccentric loading and unloading | ☑ |

| Robot park positioning button | ☑ |

Halter SmartControl Enables the Following Optional Functionalities

| Workpiece Turnover Function for Two-Sided Machining | Option |

|---|---|

| Unloading Workpiece on Pallet | Option |

| Unloading Workpiece on External Fixed Position, e.g. Conveyor Belt | Option |

| Unloading of Residual Material | Option |

| Collecting a Workpiece from a Revolver Tool | Option |

| Cleaning of Workpiece Outside the CNC Machine | Option |

| Positioning Workpiece on Measuring Station | Option |

| Removal of Rejected Workpieces | Option |

| Workpiece Side-Gripping | Option |

| Radial Positioning of the Workpiece in the Chuck | Option |

| Shaft Handling | Option |

| Customer-Specific Functionalities | On Request |

Grippers

| Description | Option |

|---|---|

| 2-finger gripper for rectangular workpieces | Option |

| 3-finger gripper for round workpieces | Option |

| 2-finger gripper for shaft handling | Option |

| Separate grippers for raw and machined workpieces | ✓ |

| Airblow system | ✓ |

| Workpiece detection system by open/close message | ✓ |

| Quick change system for exchanging grippers | Option |

| Quickly adjustable gripper fingers | ✓ |

| Workpiece-specific gripper fingers | Option |

| Pressure sensor on the robot arm monitors air pressure | UNIVERSAL |

Safety

| Functionality | Option |

|---|---|

| In-machine-space function | ✓ |

| Fanuc DCS area in combination with the Sick floor scanner | ✓ |

| Sliding door provided with safety sensors | ✓ |

| Standard safety fence between CNC machine and the Halter | ✓ |

| Automatic servo-driven door opener with integrated safety mechanism | Option |

| Closed safety circuit | ✓ |

Input

| Property | Value |

|---|---|

| Voltage | 400 V |

| Peak Consumption | 16 A / 32 A |

| Compressed Air Pressure | 6.5 bar |

Dimensions

| Property | Value |

|---|---|

| Length | 2800 mm |

| Width | 2250 mm |

| Height | 2220 mm |

| Total weight | 2490 kg / 2800 kg |

Capacity

| Property | Value |

|---|---|

| Workpiece Diameter (Min - Max) | 10 mm - 300 mm |

| Minimum Workpiece (Length x Width) | 10 mm x 10 mm |

| Maximum Workpiece (Length x Width) | 300 mm x 300 mm |

| Height of Workpiece (Min - Max) | 10 mm - 300 mm |

| Maximum Load Capacity of Robot Arm | 35 kg / 70 kg |

| Maximum Total Weight on Rotating Table | 3000 kg |

| Max. Number of Workpieces for Grid Plate 10-35 mm | 320 |

| Max. Number of Workpieces for Grid Plate 23-55 mm | 206 |

| Max. Number of Workpieces for Grid Plate 23-85 mm | 112 |

| Max. Number of Workpieces for Grid Plate 23-115 mm | 66 |

| Max. Number of Workpieces for Grid Plate 23-135 mm | 52 |

| Max. Number of Workpieces for Grid Plate 23-175 mm | 28 |

| Max. Number of Workpieces for Grid Plate 23-195 mm | 24 |

| Max. Number of Workpieces for Grid Plate 23-230 mm | 18 |

| Max. Number of Workpieces for Grid Plate 23-300 mm | 10 |

| Workpiece-Specific Grid Plates | Option |

Capacity for Shaft Handling

| Property | Value |

|---|---|

| Workpiece Diameter (Min - Max) | 10 mm - 300 mm |

| Minimum Workpiece (Length x Width) | 10 mm x 10 mm |

| Maximum Workpiece (Length x Width) | 300 mm x 300 mm |

| Height of Workpiece (Min - Max) | 10 mm - 300 mm |

| Maximum Load Capacity of Robot Arm | 35 kg / 70 kg |

| Maximum Total Weight on Rotating Table | 3000 kg |

| Max. Number of Workpieces for Grid Plate 10-35 mm | 320 |

| Max. Number of Workpieces for Grid Plate 23-55 mm | 206 |

| Max. Number of Workpieces for Grid Plate 23-85 mm | 112 |

| Max. Number of Workpieces for Grid Plate 23-115 mm | 66 |

| Max. Number of Workpieces for Grid Plate 23-135 mm | 52 |

| Max. Number of Workpieces for Grid Plate 23-175 mm | 28 |

| Max. Number of Workpieces for Grid Plate 23-195 mm | 24 |

| Max. Number of Workpieces for Grid Plate 23-230 mm | 18 |

| Max. Number of Workpieces for Grid Plate 23-300 mm | 10 |

| Workpiece-Specific Grid Plates | Option |

Documents and brochures

Do You Need Help?

We are here to provide you with all the information and assistance you need regarding our products. Please fill out the contact form below, and we will promptly answer your questions or provide you with the support you need to make the right decisions.

News and events

Join the most important events and stay up to date with the latest industry news

Forumul de Inovație ZEISS & Marea Deschidere INMAACRO Timișoara I 19.03.2026

Avem plăcerea de a vă invita la evenimentul de inaugurare a noului laborator de măsurări din Timișoara, unde vă vom prezenta soluții pentru controlul calității, pe 19 Martie, începând cu ora 09:30. Experimentați universul metrologiei în cadrul unei expoziții interesante și prin prezentări interactive!

Ziua Calității ZEISS 2025 | 06.11.2025

Pe 6 Noiembrie, pregatiți-vă pentru un workshop exclusiv dedicat profesioniștilor în controlul calității. Descoperiți soluții concrete pentru provocările din producție, participați la demonstrații live cu echipamente de ultimă generație și beneficiați de consultanță personalizată pentru a vă optimiza procesele de măsurare.

Technical News in Turning and Grinding – WORKSHOP | 08.05.2025

We invite you to an event dedicated to the latest technical solutions in the field of turning and grinding! Together with our top partners – BRUCKNER, BLOHM JUNG, INDEX, STUDER, WALTER EWAG – you will explore the most advanced technologies and attend live demonstrations that will address the needs and challenges you face in your activity.

Ziua Calității ZEISS 2024 | 21 Noiembrie 2024

Vă invităm la un nou eveniment anual exclusiv în care vom prezenta pentru a treia oară soluții de asigurare a calității împreună cu partenerul nostru ZEISS. Explorați împreună cu noi lumea metrologiei industriale ZEISS..

Halter Universal Big 35/70

Halter Universal Big 35/70